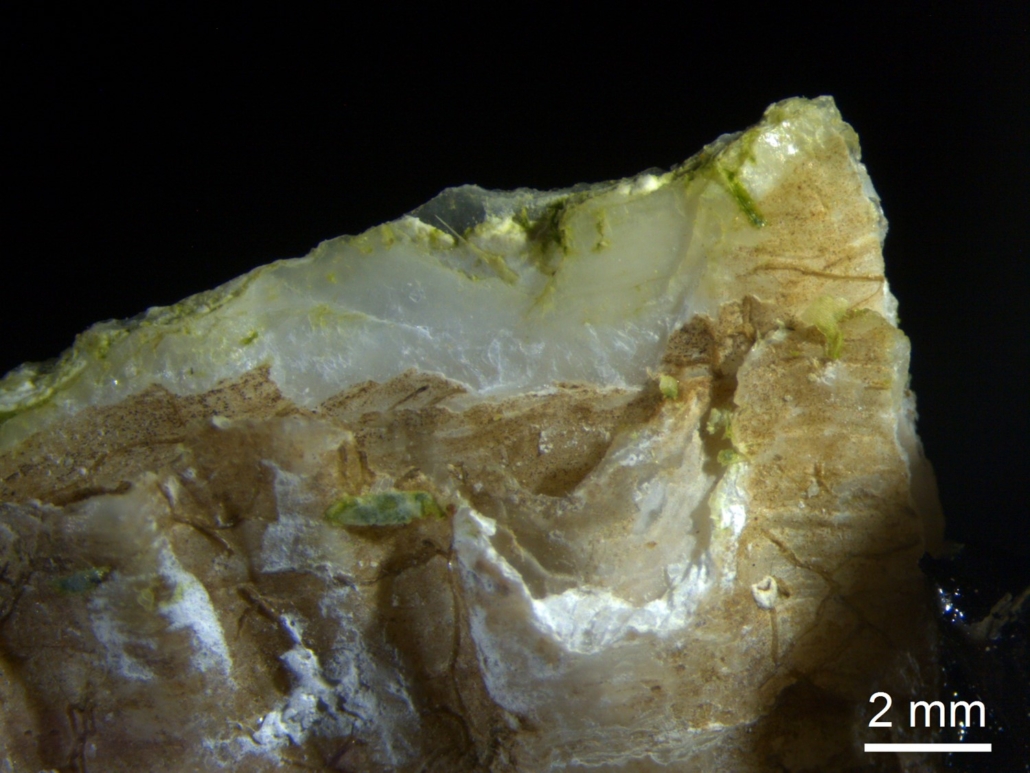

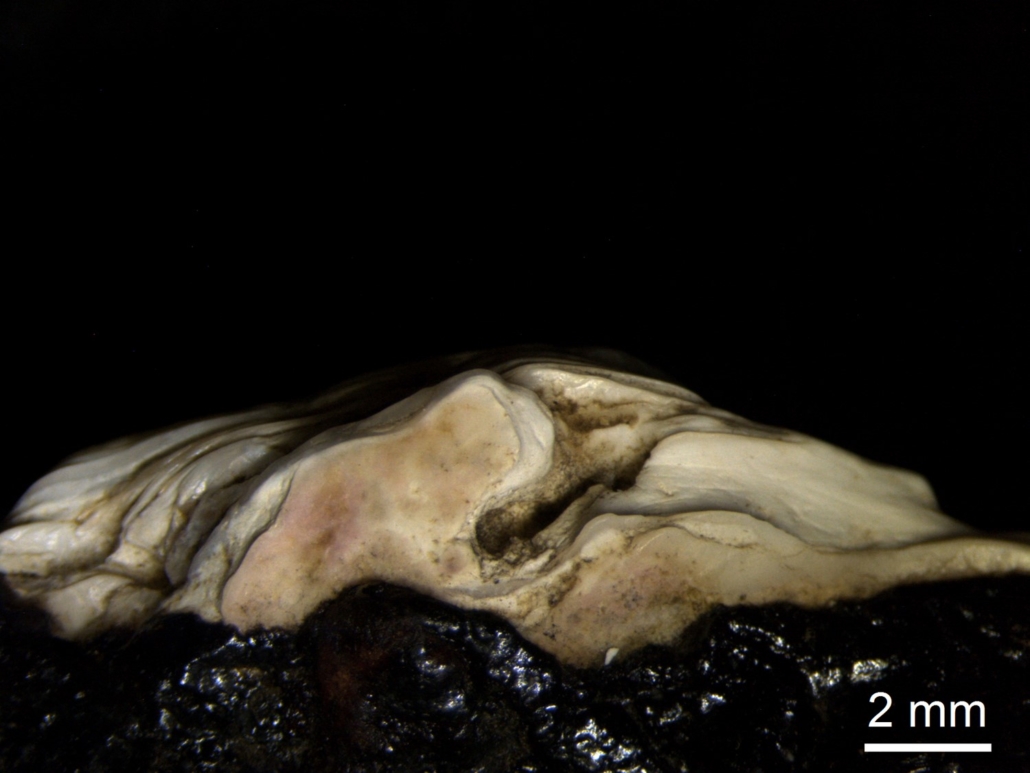

In the Vlaardingen Culture period (3400-2500 BCE) tools were made from a wide range of materials such as flint, wood, bone, and antler. Bone tools were often made using the ‘metapodium technique’. This technique was especially useful when making awls or chisels. Metapodia are long, sturdy, bones in the lower parts of the legs of animals such as deer and cattle. These bones have natural grooves running centrally along the length of the bone (see figure 1). Using a flint tool people deepened these grooves by carving the bone up and down the shaft. After this the distal end of the bone was sawn-off with another flint tool. Next, the bone was split in halves along the deepened grooves in the center of the bone. These halves served as blanks. Using a grinding stone people could either turn these into a chisel by grinding a chisel-shaped flat edge on one end, or they could grind them into a pointed end to make an awl.

Figure 1. Scheme with the metapodium technique (Van Gijn 1990, 109).

In a recent study, published in the Journal of Archaeological Science: Reports, we were able to demonstrate that this technique was only widely applied when deer bone was widely available (Van den Dikkenberg and Van Gijn 2024). In the study we combined the results of our micro-wear analysis with previously published zooarchaeological studies. Since the Mesolithic (when people were still hunter gatherers) people preferred to use deer bones for the production of these tools. During the Vlaardingen Culture period people began to rely more on cereal cultivation and cattle herding. The metapodium technique was still widely applied on sites where deer was frequently hunted, but it could be observed that this technique was uncommon on sites where people relied mostly on cattle herding. It is interesting to note that even though subsistence strategies radically changed during the Neolithic, in which people increasingly relied on agriculture, deer still maintained an important position in these societies.

Literature

Van den Dikkenberg, L., and A.L. van Gijn, 2024. Deer ghosts: Invisible bone tools from the Vlaardingen Culture (3400–2500 BCE), bone-working, toolkits, and cultural preferences. Journal of Archaeological Science: Reports 56 (Special Issue Tracing Social Dynamics” Proceedings of the 3rd Association of Archaeological Wear and Residue Analysts (AWRANA) Meeting (Barcelona 2022)). 104569. https://doi.org/https://doi.org/10.1016/j.jasrep.2024.104569

Van Gijn, A.L., 1990. The wear and tear of flint. Principles of functional analysis applied to Dutch Neolithic assemblages 22.

Yuri van Koeveringe

Yuri van Koeveringe