By: Lasse van den Dikkenberg

This post will deal with Buren axes, flint axes which were imported during the Vlaardingen Culture period (3400-2500 BC). The post is based on an experiment conducted by Diederik Pomstra whom reconstructed several Buren axes. These axes were then re-used as a source of flint for the creation of smaller objects. Our aim was to gain more insight into the re-use of Buren axes as a raw material source.

Raw material

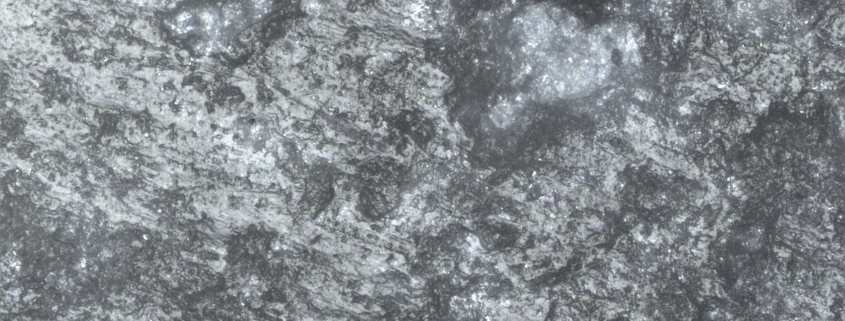

Nearly everything the people from the Vlaardingen Culture used was produced locally. The most striking exception to this rule are the so called Buren axes. Flint raw material sources are scarce in the wetland areas of the Vlaardingen Culture and especially large nodules are hard to come by. In Belgium and the southern Netherlands flint is abundant and several Neolithic flint mines in the area produced large quantities of raw material. Flint from these areas was transported over large distances, even before the Vlaardingen Culture period. By this time people in the wetland areas of the Western Netherlands stopped producing their own axes. All axes they used were thus imported from other regions. The vast majority of axes we find in the Vlaardingen Culture area are so called “Buren axes” which are characterised by their oval cross-section. Their abundance in this area initially led scholars to call them “Vlaardingen axes” even though it was later realised that they were not produced by Vlaardingen people (Bakker 2006, 263; Van Regteren Altena et al. 1962, 240).

These axes were mainly produced by the southern neighbours of the Vlaardingen people, the Stein

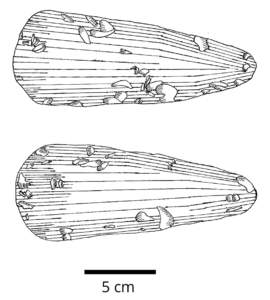

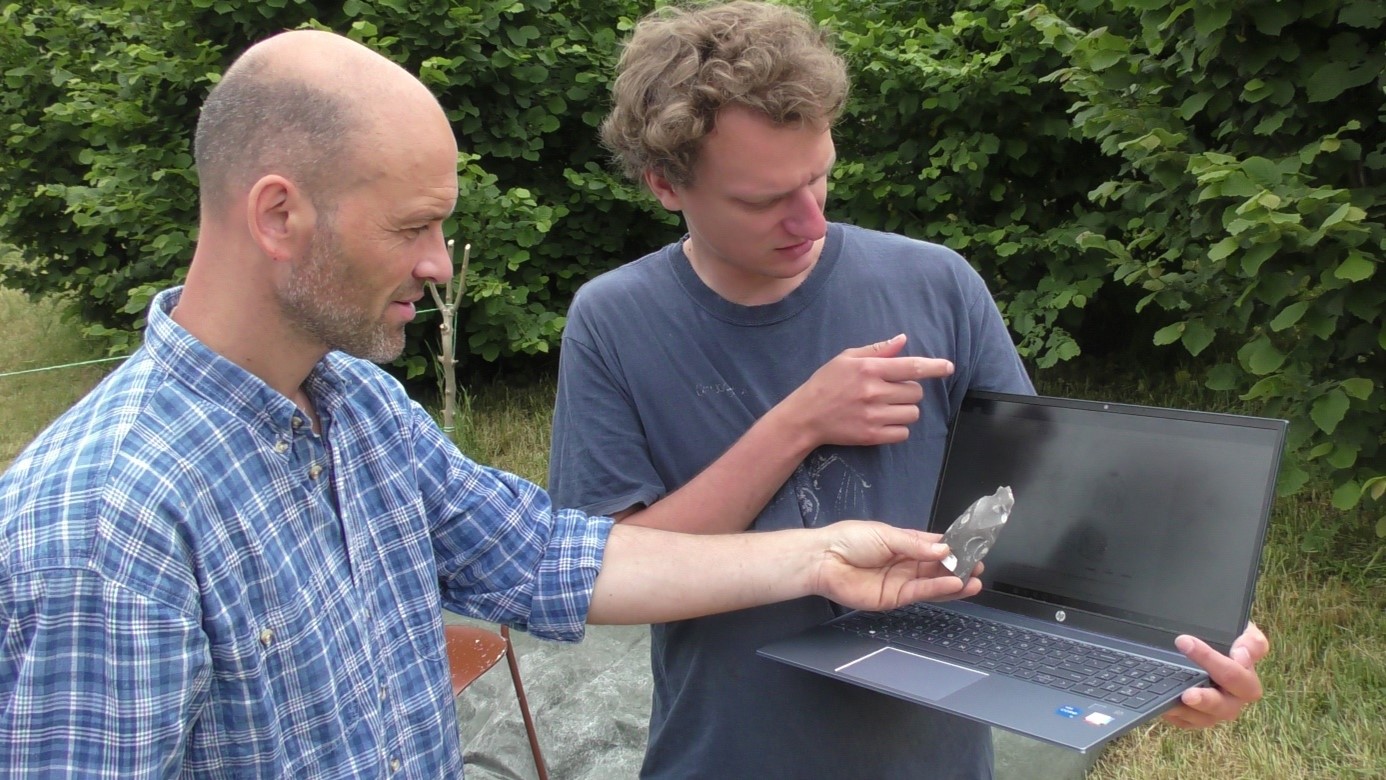

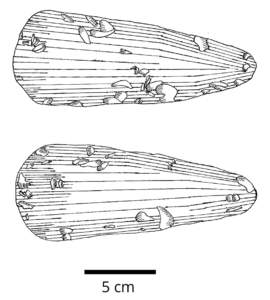

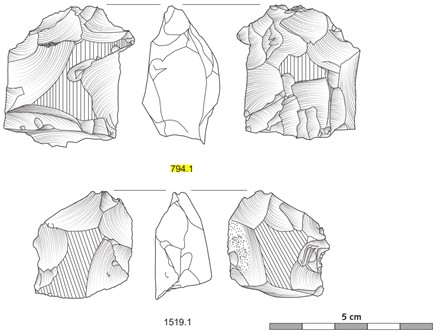

Fig 1. Drawing of one of the flint axes used in the experiment.

group. The two groups are closely related but they are thought to represent slightly different traditions. The Stein people exploited the Neolithic flint mines where they dug-up large flint nodules which were enclosed in layers of limestone. The nodules were flaked into roughouts in locations near the flint mines. These roughouts were then transported to nearby villages where they were ground into their final shape. These polished axes were then often transported to other areas and groups (Bakker 2006, 263).

Flaking flint axes

For our experiment Diederik Pomstra created three flint axes. The first step was to select suitable large flint nodules. The nodules had to be big, but they were also selected to be not too large as flaking them into the right size would mean a lot of extra work. For one axe we used Rijkcholt flint, which was also used in prehistory for Buren axes. For the other axes we used northern flint from Northern Germany and Denmark as we still had some large nodules of this material. The axes were flaked in a bifacial manner. This is one of the oldest and most common flaking techniques. It was already used over a million years ago to produce Palaeolithic handaxes and the technique remained in use well into the Bronze Age for the production of daggers and arrowheads. Bifaces have more or less oval cross-sections which allow you to strike large flakes from the surface.

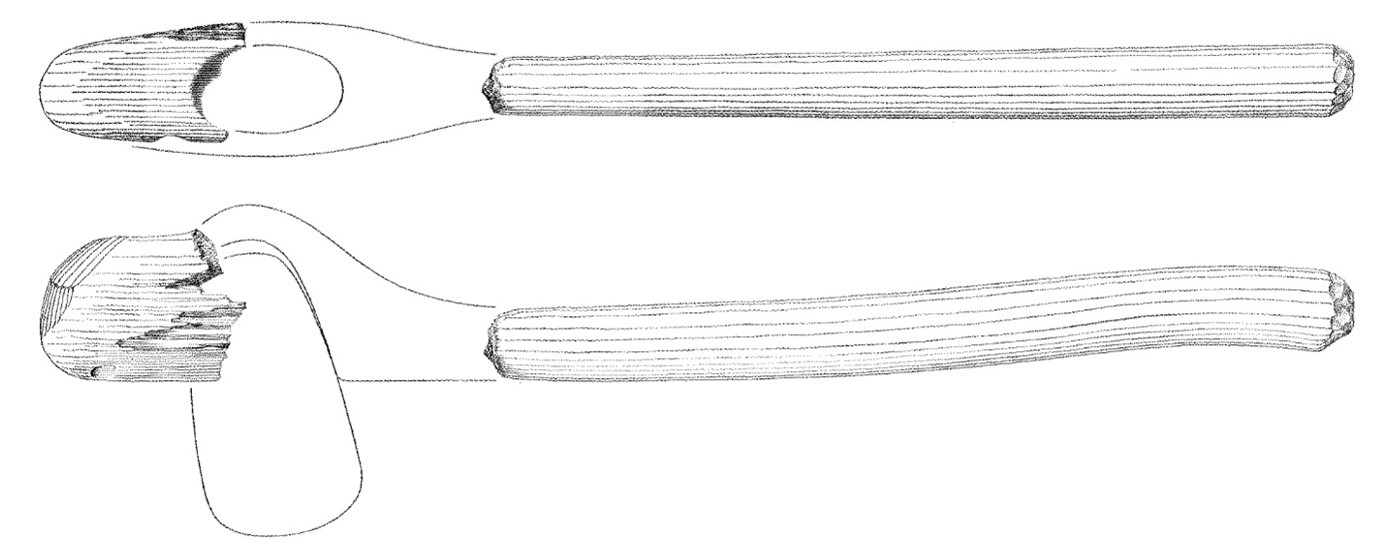

Figure 2. Reconstructed Buren axe roughout made by Diederik Pomstra.

The method is very efficient and relatively easy, especially when compared to the production sequence of rectangular axes, which were used by the contemporary Funnel Beaker Culture in the Northern Netherlands. Diederik Pomstra, being an experienced knapper, was able to flake a Buren axe in about twenty minutes. Which I thought was surprisingly quick.

Figure 3. Diederik Pomstra knapping one of the Buren axes for the experiment.

Grounding Buren axes

But flaking is only the first step in the creation of these axes. Most time was spend on grounding the axes. If done by hand, this would take a full day for a single axe. Compared to flaking the grounding work is fairly easy. It is not surprising that, even though the axes were flaked near the flint mines, the grounding of the axes took place in a wider area. If one person would spend time flaking axes for an entire day several people would be needed to ground all the axes in order to keep up the pace.

Hafting and using axes

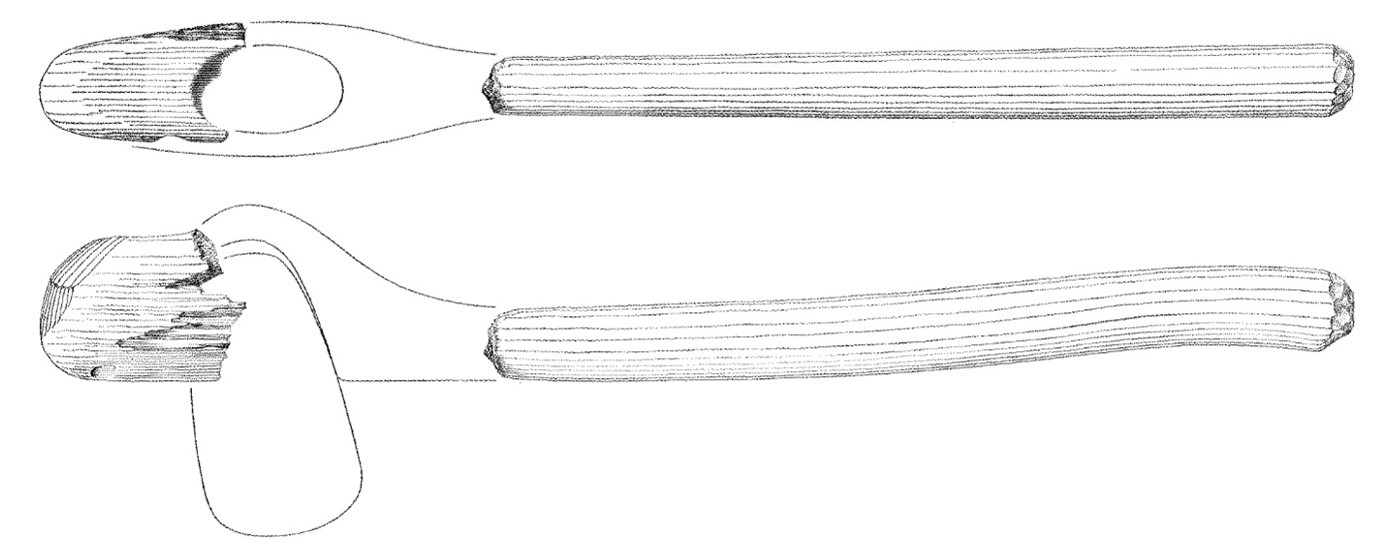

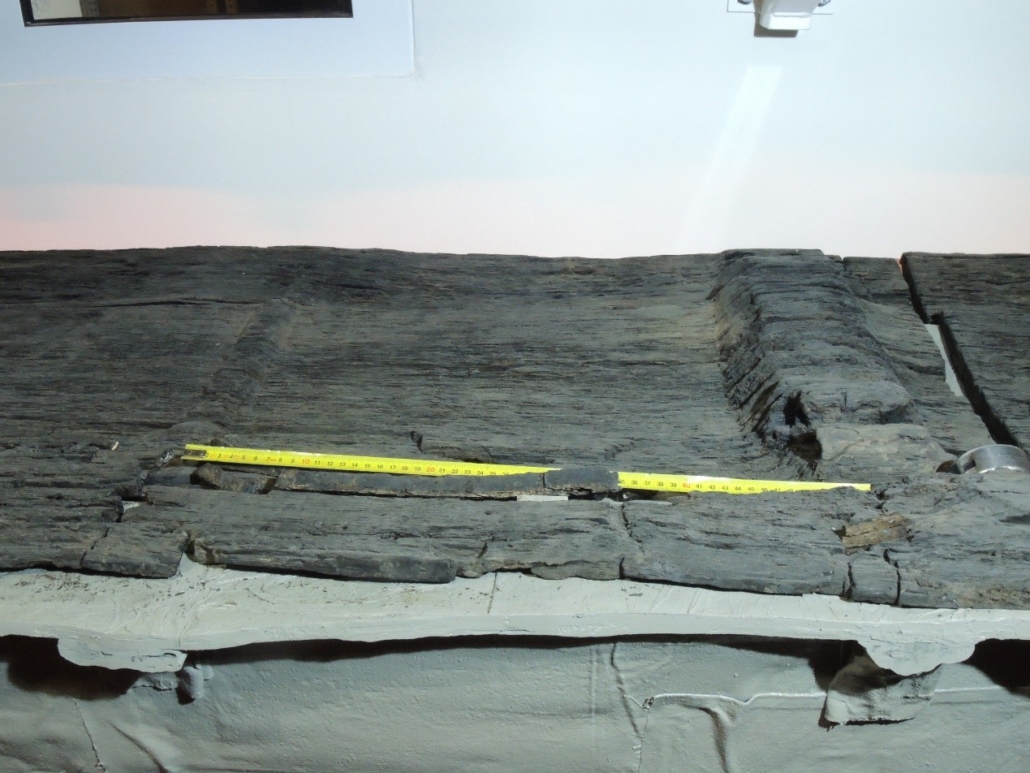

After grounding the flint axes were usually hafted into a wooden shaft. Two parts of wooden axe shafts were found at the site Hazendonk so we know quite well how these axes could have been hafted. It is unclear if Vlaardingen people imported hafted axes or if they only imported the flint axe. It seems most likely that people were able to produce their own axe hafts as the raw material for these was locally available.

Figure 4. Two parts of a wooden axe handle found at Hazendonk used to reconstruct the hafting method for Buren axes (Van Gijn and Louwe Kooijmans 2005, 350).

Occasionally the flint axe was hafted first into a piece of antler before being hafted in the wooden shaft. The antler serves to lessen the impact shock, thereby protecting the flint from breakage.

These axes were presumably mainly used in woodworking. They would have been used to construct houses, tools and dugout canoes.

Figure 5. Diederik Pomstra using a flint Buren Axe to build a wooden dugout canoe.

Axes as flint sources

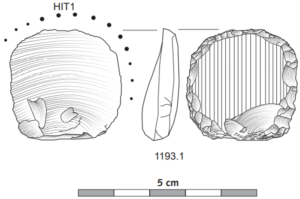

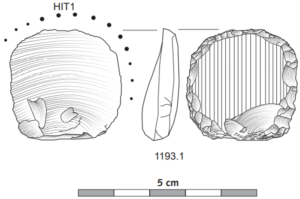

Figure 6. Drawing of a flint scraper which was made from a ground axe fragment, the ground surface is indicated by the vertical lines in the right drawing (Houkes et al. 2017, 181).

Because flint was scarce in the Vlaardingen area people had to make do with the limited resources they had access to. The imported flint axes were much larger in size than the flint nodules which people could collect locally. At some point these axes fell into disuse, presumably because they broke or because they became too small to keep up resharpening them. Rather than being discarded, these axes were frequently re-used as a source of flint for new objects. This re-use of axes was by no means incidental. Approximately 10-20% of all flint on Vlaardingen sites consist of axe fragments (Van Gijn and Bakker 2005, 295). The axes or broken fragments were flaked into flakes which were either used directly or which were then shaped into other kinds of objects such as scrapers or borers. These objects can be recognised as being axe fragments because of the ground and polished surface of the axes. However, it is unclear to what extend flaking these axes into smaller objects will also produce flakes where the ground and polished surface of the axes is no longer visible. This is an important variable. For example: if only half of the flakes from polished axes are recognisable as axe fragments that would mean that 20-40% (rather than 10-20%) of the flint on Vlaardingen sites consists of axe fragments. Furthermore, it is also unclear how many flakes and blanks for other objects can be struck from a single axe. Can one axe produce two scrapers? Or can a single axe be used to create dozens of scrapers?

Setting-up the experiment

For the experiment Diederik Pomstra created three flint axes. Buren axes vary in length between 15 and 25 cm (Bakker 2006, 257). We chose to create rather short axes between 16 and 17,5 cm. This scenario presumably most closely resembled axes which were used, then ground repeatedly (shortening them), which led to them being re-used as a source of flint for other objects. In two instances we decided to break the axes into halves using a bipolar technique. By doing this we were able to replicate an end-shock fracture (which occurs when a flint axe breaks in the shaft during heavy work). The third axe was kept whole to simulate an ideal scenario in which a whole axes was re-used as a source of flint.

Figure 7. I had the honour of breaking the axes to simulate the end-shock fractures on the first two axes.

Conducting the experiment

We conducted the experiment in Masamuda during the National (and European) Archaeology Days. The flint knapping was done by Diederik Pomstra. We used a plastic sheet to collect all the flint particles during the knapping process. We soon realised that there were many possible reduction sequences one could envision. It was for example quite possible to turn the axe halves into blade cores. But there is no evidence for the use of blade cores in the Vlaardingen Culture. Hence we decided to focus on the production of flakes.

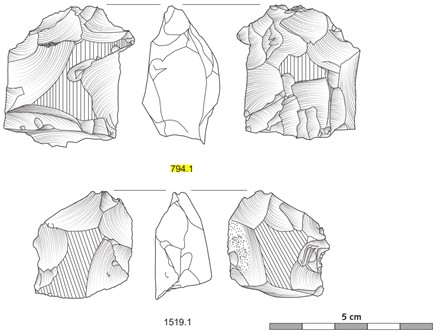

Figure 8. Flint axe cores from Den Haag Wateringse Binnentuinen (Houkes et al. 2017, 172).

For one axe half we decided to more or less reconstruct the reduction sequence which would result in cores similar to the axe cores from Den Haag Wateringse Binnentuinen (see figure 7). Here it was clear that the cores were worked either from the butt to the centre or from the cutting edge to the centre. The end shock platform was largely left intact. This was seen as an odd choice by Diederik Pomstra who thought the end-shock fracture actually provided a very suitable platform to begin a reduction sequence. We attempted to follow the reduction sequence as visible from these cores. This meant that flakes were struck from the butt end or cutting edge and from the sides of the axe alternately. We aimed to produce large flakes in the process as these would be most suitable for the creation of tools such as scrapers, strike-a-lights and borers.

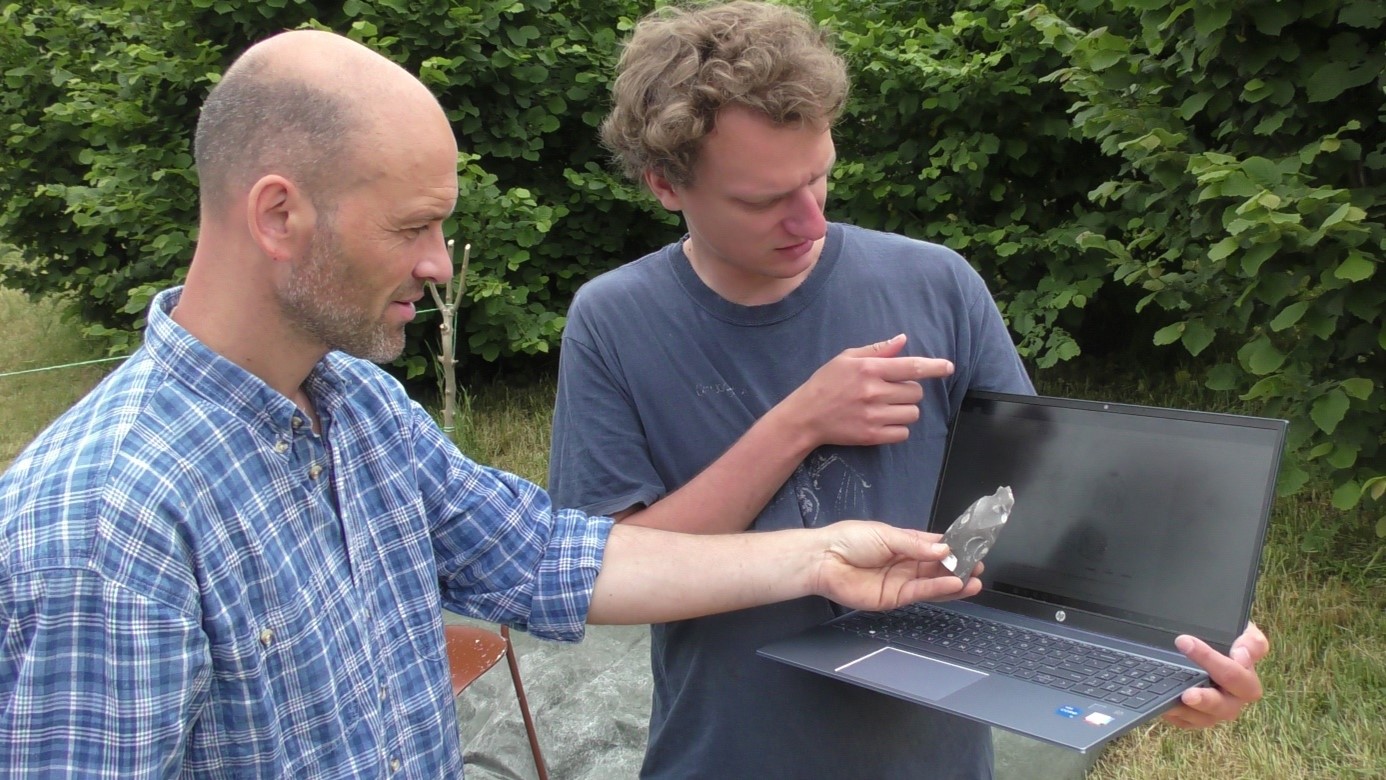

Figure 9. Discussing the potential reduction sequence with Diederik Pomstra.

For one axe we decided not to stop at the moment when we reached a core which resembled those from Den Haag Wateringse Binnentuinen. It was quite clear that from these cores more suitable flakes could have been struck. Therefore we decided to continue reducing the axe until no suitable flakes could be struck anymore. Here our aim was to have a maximum yield in terms of suitable flakes.

Preliminary results

The results of the experiment still have to be analysed but already some things became apparent. The broken axes could have efficiently be turned into blade cores but there are no archaeological indications that the Vlaardingen People used axes as blade cores. This further confirms the notion that these people were presumably not familiar with blade technologies, since they didn’t use these even when the raw material sources were well suited for this.

We haven’t counted the flakes yet but we can roughly estimate that between 20-50 suitable flakes could be struck from a single axe. By contrast the small locally available rolled nodules of flint can be used generally to create two blanks, using a bipolar technique. It is thus clear that these axes, even in a worn and broken state, provided a superior source of quality flint. The experiments give us an insight into the choices people made when selecting raw material and when working with these materials.

The next step will be to determine to what extend these flakes are still recognisable as axe fragments. If some of these flakes are not recognisable as axe fragments that would mean that a larger percentage of flakes from the archaeological record would have been part of axes. Extrapolating those results can help us to better assess the importance of flint axes as raw material sources in the Vlaardingen Culture.

Literature

Bakker, J.A., 2006. The Buren Axe and the Cigar Chisel: striking export products from the West European flint mines – associations and distribution along their northern fringe, in: G. Körlin and G. Weisgerber (eds.), Stone Age – Mining Age, Bochum (Veröffentlichungen aus dem Deutsches Bergbau-Museum Bochum 148 (Der Anschnitt: Beiheft 19)) 247-275.

Gijn, A.L. van and J.A. Bakker 2005. Hunebedbouwers en steurvissers Midden-Neolithicum B: trechterbekercultuur en Vlaardingen-groep, in: L. P. Louwe Kooijmans, P. W. Van der Broeke, H. Fokkens and A. L. Van Gijn (eds.), Nederland in de Prehistorie, Amsterdam University Press, Amsterdam, 281-306.

Gijn, A.L. van and L.P. Louwe Kooijmans, 2005. De eerste boeren: synthese, in: L. P. Louwe Kooijmans, P. W. Van der Broeke, H. Fokkens and A. L. Van Gijn (eds.), Nederland in de Prehistorie, Amsterdam University Press, Amsterdam, 337-353.

Houkes, R., A. Verbaas and R. Mullaart, 2017. Vuursteen, in: P.A.J. Stokkel, E.E.B. Bulten (red.), De Wateringse Binnentuinen Gemeente Den Haag, Een Vlaardingennederzetting in het Wateringse Veld, Haagse Oudheidkundige Publicatie 20. Den Haag: Afdeling Archeologie & Natuur- en Milieueducatie Dienst Stadsbeheer, 163-204.

Regteren Altena, J.F. van, J.A. Bakker, A.T. Clason, W. Glasbergen, W. Groenman-van Waateringe and L.J. Pons, 1962. The Vlaardingen Culture (III), Helinium 2, 215-243.

Yuri van Koeveringe

Yuri van Koeveringe

Yuri van Koeveringe

Yuri van Koeveringe